Welcome aboard! When it comes to railroad tracks, safety and stability are paramount. After all, these steel giants carry heavy loads and enable transportation across vast distances. But have you ever wondered what keeps those tracks securely in place? That's where rail clamp plates come into play. These unassuming yet essential components play a crucial role in maintaining the integrity of railway lines worldwide. In this blog post, we'll delve into the world of rail clamp plates, exploring their types, installation process, and highlighting why they are vital for securing railroad tracks. So fasten your seatbelts, as we embark on an informative journey about Longyu Track Materials and how they help keep trains chugging along smoothly!

What are Rail Clamp Plates?

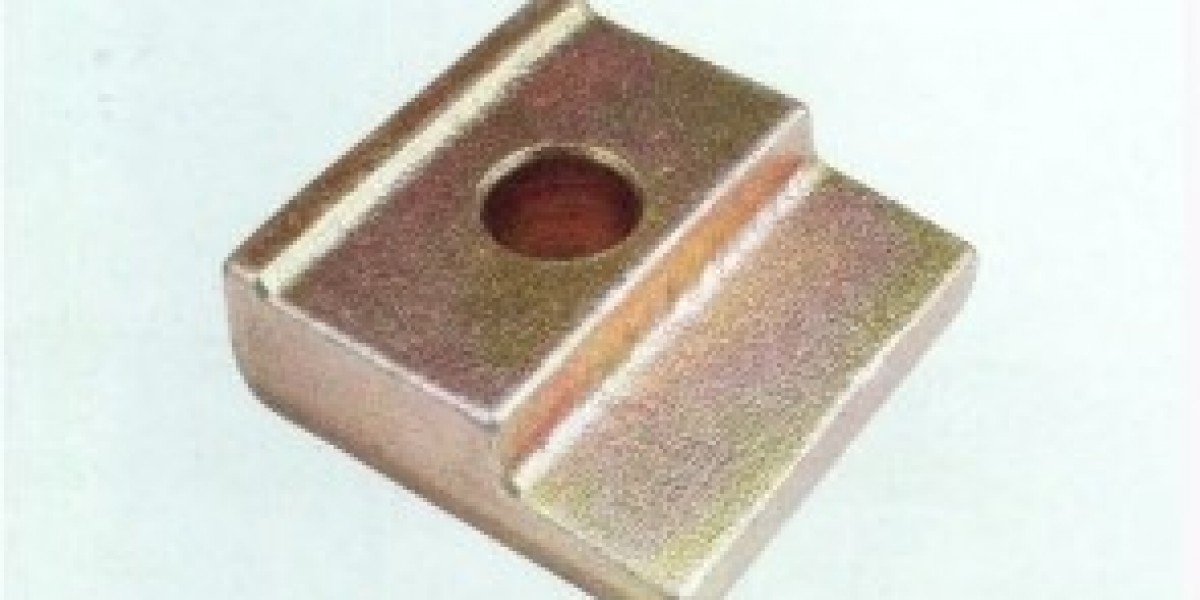

Rail clamp plates, also known as rail clips or rail clamps, are essential components used in railway systems to secure and stabilize railroad tracks. These small yet mighty devices serve a crucial purpose: holding the rails firmly in place, preventing any lateral movement that could lead to accidents or derailments.

Made from high-quality materials such as steel or iron, rail clamp plates are designed to withstand extreme weather conditions and heavy loads. Their sturdy construction ensures long-lasting performance and durability, making them ideal for railway applications.

These plates work by gripping onto the base of the rail, exerting pressure that locks it into position. This frictional force helps prevent any movement caused by vibrations or train traffic passing over the tracks. Additionally, rail clamp plates distribute the load evenly across the entire length of the track, reducing stress concentration points and enhancing stability.

Rail clamp plates come in various shapes and sizes to accommodate different types of rails and track configurations. From single shoulder designs to double shoulder variants, there is a wide range of options available based on specific requirements.

Installation of rail clamp plates is relatively straightforward. Typically positioned at predetermined intervals along the track's length, they are secured using bolts or welding techniques. The process requires precision and expertise to ensure proper alignment and fastening for optimal performance.

Overall, rail clamp plates play an indispensable role in maintaining safe and reliable railway operations. Their ability to securely hold tracks together enhances safety for both passengers and cargo alike.

With their robust construction, diverse range of options, and simple installation process, railway companies can trust these unassuming yet vital components to keep their tracks secure for years to come.

The Importance of Securing Railroad Tracks

Railroad tracks are an integral part of our transportation infrastructure, facilitating the movement of goods and people across vast distances. Ensuring their safety and stability is of utmost importance to prevent accidents and disruptions in rail operations. This is where the importance of securing railroad tracks comes into play.

Securing railroad tracks not only enhances safety but also improves track reliability and longevity. Without proper security measures, tracks can become loose or misaligned over time, leading to derailments or other incidents. By using rail clamp plates, these risks can be minimized.

Rail clamp plates provide a crucial connection between rails, ensuring they remain securely fastened together. These plates help distribute the load evenly across the track system, reducing stress on individual components and preventing excessive wear and tear.

By choosing appropriate rail clamp plates for specific track conditions, such as heavy traffic or harsh weather conditions, railway authorities can significantly enhance track stability and durability. Different types of rail clamp plates are available in the market to cater to various requirements.

The installation process of rail clamp plates is relatively straightforward but requires expertise and precision to ensure optimal performance. It involves removing any existing bolts or fasteners from the rails before attaching the plate securely with new bolts or welding techniques if necessary.

Using rail clamp plates offers numerous benefits beyond just securing railroad tracks. They improve overall track integrity by minimizing maintenance needs caused by loose rails or shifting components. This leads to cost savings for railway operators in terms of reduced repair work and enhanced operational efficiency.

Additionally, secure railroad tracks contribute to passenger comfort by ensuring smoother rides with minimal vibrations or jolts during train journeys. Freight transport also becomes safer as securely fixed rails reduce the risk of cargo shifts that could potentially lead to accidents.

Types of Rail Clamp Plates

Rail clamp plates are crucial components in securing railroad tracks, and they come in various types to cater to different track requirements. Each type of rail clamp plate offers unique features and benefits, ensuring the stability and safety of the railway system.

One common type is the elastic rail clip plate, which is designed to provide a flexible grip on the rails. It helps absorb vibrations and dynamic forces caused by passing trains, reducing wear and tear on both the rails and other track components. This type of rail clamp plate ensures a secure fit while allowing some movement to accommodate temperature changes.

Another type is the self-locking rail clamp plate, known for its excellent locking capability. It prevents any unwanted movement or displacement of the rails by tightly securing them in place. The self-locking mechanism provides enhanced stability even under heavy loads or extreme weather conditions.

Additionally, there are also adjustable rail clamp plates that allow for easy installation and adjustment without requiring specialized tools. These plates can be quickly adjusted to fit varying rail sizes, making them versatile options for maintenance or replacement projects.

Furthermore, composite material rail clamp plates have gained popularity due to their durability and resistance against corrosion. Made from high-quality materials like Longyu Track Materials, these plates offer exceptional strength while being lightweight at the same time.

In conclusion, With an array of types available ranging from elastic clips to self-locking mechanisms and adjustable designs made from reliable materials like Longyu Track Materials, rail clamp plates ensure optimal security for railroad tracks. Their diverse characteristics address specific needs such as flexibility, stability, and ease of installation. By incorporating these essential components into railway systems, the overall efficiency and longevity of tracks are significantly improved

Installation Process of Rail Clamp Plates

Installing rail clamp plates is a crucial step in securing railroad tracks and ensuring the safety and stability of train operations. The process involves several key steps that must be followed to ensure proper installation.

First, the area where the rail clamp plates will be installed needs to be prepared. This includes cleaning the surface of any debris or dirt that may interfere with the installation. It is important to create a smooth and stable foundation for the rail clamp plates.

Next, position the rail clamp plate over the designated spot on the track. Make sure it aligns properly with both rails to ensure a secure fit. Then, using appropriate tools, fasten the plate securely onto each rail. This typically involves tightening bolts or screws to hold it firmly in place.

After attaching all necessary rail clamp plates along the track, perform a thorough inspection to ensure they are installed correctly and securely. Check for any loose fittings or signs of damage that could compromise their effectiveness.

Installing rail clamp plates requires precision and attention to detail. By following these steps carefully, you can help maintain safe and reliable railroad tracks for efficient train transportation.

Benefits of Using Rail Clamp Plates

Rail clamp plates play a crucial role in securing railroad tracks, providing numerous benefits that contribute to the efficiency and safety of railway systems. These sturdy plates are designed specifically to hold the rails together firmly, preventing any movement or dislocation.

One of the significant advantages of using rail clamp plates is their ability to distribute loads evenly across the tracks, ensuring better weight distribution and reducing stress on individual components. This helps prevent wear and tear, prolonging the lifespan of both the rails and other track materials.

In addition to improving stability, rail clamp plates also enhance safety by minimizing track movement. By securely fastening adjacent rails, these plates help maintain proper alignment and reduce the risk of derailments or accidents caused by misaligned tracks.

Rail clamp plates are easy to install and require minimal maintenance compared to alternative methods such as welding or bolting. This not only saves time but also reduces costs associated with regular repairs or replacements.

Furthermore, rail clamp plates offer versatility as they can be used with various types of rail sections including flat-bottomed rails and grooved rails. Their compatibility allows for greater flexibility in track design while maintaining consistent performance standards.

By utilizing rail clamp plates, railway operators can enjoy improved operational efficiency due to reduced downtime for maintenance purposes. With increased stability and decreased risks of accidents or track damage, trains can run smoothly at optimal speeds without disruptions.

It is clear that using rail clamp plates provides numerous benefits for securing railroad tracks effectively. From enhanced safety measures to cost savings through reduced maintenance requirements, these essential components play a vital role in maintaining reliable railway infrastructure.

Conclusion

Rail clamp plates play a crucial role in securing railroad tracks and ensuring the safety and efficiency of train operations. These essential components help to prevent track misalignment, reduce wear and tear on rails, enhance stability, and minimize the risk of accidents.

With various types available in the market, including the resilient rubber pad type and adjustable rail clamp plate type, railway engineers have options that can cater to different track requirements. The installation process is straightforward and can be done efficiently with proper equipment and expertise.

By utilizing rail clamp plates in railway infrastructure projects, we not only improve track stability but also ensure smoother journey experiences for passengers while reducing maintenance costs. With their ability to withstand heavy loads and extreme weather conditions without compromising performance or safety standards, these materials are truly invaluable assets within the world of railways.

When it comes to sourcing reliable rail clamp plate suppliers who offer high-quality products like Longyu Track Materials', it's essential to prioritize durability, precision engineering, adherence to industry standards, and excellent customer service.

So whether you're involved in railway construction or maintenance projects or simply interested in understanding more about this critical component of our transportation system - remember that rail clamp plates are an integral part of keeping trains on track!