Gasketed plate heat exchangers are widely used in various industries for their efficiency in transferring heat between two fluids. The B30B model is a popular choice for many applications due to its design and performance. In this article, we will explore the working principles of the gasketed plate heat exchanger B30B, detailing its components, operation, and advantages.

Overview of Gasketed Plate Heat Exchanger B30B

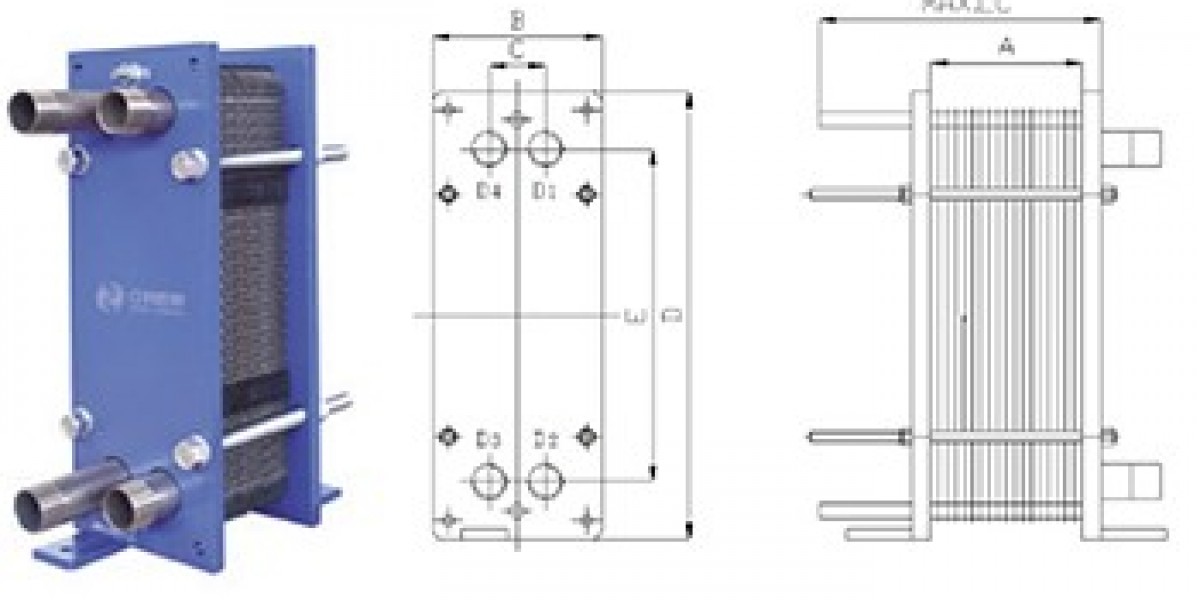

Thehttps://www.yojointernational.com/Gasketed-Plate-Heat-Exchanger/Gasketed-Plate-Heat-Exchanger-B30B.shtmlis a compact and efficient heat exchanger that consists of a series of plates with gaskets in between. These plates are corrugated to create a large surface area for heat transfer between the two fluids. The B30B model is designed for high thermal efficiency and can handle a wide range of flow rates and temperature differentials.

Components of Gasketed Plate Heat Exchanger B30B

Thegasketed plate heat exchanger B30Bcomprises several key components that work together to facilitate heat transfer between two fluids. These components include:

Plates: The plates in the B30B heat exchanger are typically made of stainless steel or other heat-conductive materials. The plates are corrugated to increase the surface area available for heat transfer.

Gaskets: Gaskets are placed between the plates to create tight seals and prevent leakage of the fluids. The gaskets are usually made of materials that can withstand high temperatures and pressures.

Frame: The frame of the heat exchanger holds the plates and gaskets together, creating a sealed unit. The frame also provides support and stability to the heat exchanger.

Connections: Inlets and outlets are connected to the heat exchanger to allow the entry and exit of the two fluids. These connections are designed to minimize pressure drop and ensure efficient heat transfer.

Working Principles of Gasketed Plate Heat Exchanger B30B

The gasketed plate heat exchanger B30B operates on the principle of counter-current flow, where the two fluids flow in opposite directions to maximize heat transfer efficiency. The hot fluid enters the heat exchanger through one set of plates, while the cold fluid enters through another set of plates. As the fluids flow through the plates, heat is transferred from the hot fluid to the cold fluid through the plate material.

Advantages of Gasketed Plate Heat Exchanger B30B

The gasketed plate heat exchanger B30B offers several advantages over traditional heat exchangers, making it a popular choice for many industrial applications. Some of the key advantages include:

Compact design: The B30B model is compact and space-saving, making it ideal for installations where space is limited.

High efficiency: The corrugated plates and gaskets in the B30B heat exchanger provide a large surface area for heat transfer, resulting in high thermal efficiency.

Easy maintenance: The modular design of the B30B heat exchanger allows for easy disassembly and cleaning, making maintenance simple and cost-effective.

Versatility: The B30B heat exchanger can handle a wide range of flow rates and temperature differentials, making it suitable for various applications in different industries.

Conclusion

Gasketed plate heat exchangers, such as the B30B model, are essential components in many industrial processes for their efficiency and reliability in heat transfer applications. By understanding the working principles and components of thegasketed plate heat exchanger B30B, engineers and operators can optimize its performance and ensure smooth operation. With its compact design, high efficiency, and versatility, the B30B heat exchanger continues to be a popular choice for a wide range of industrial applications.

Jiangsu Yuanzhuo Equipment Manufacturing CO., LTD.is also simply known as YOJO. Members of YOJO are the specialists who have gained rich experience in the heat transfer sector formany years and are holding the most advanced technology for the plate heat exchanger: research, design and manufacture.

Jiangsu Yuanzhuo Equipment Manufacturing CO., LTD.is also simply known as YOJO. Members of YOJO are the specialists who have gained rich experience in the heat transfer sector for many years and are holding the most advanced technology for the plate heat exchanger: research, design and manufacture.

Welcome to work with YOJO, we will provide the best gasketed plate heat exchangerssolution for your specific needs.

E-mail:zy@jsyuanzhuo.com